Power Systems Analysis

Expertise, experience, and tools to accurately analyze power systems.

The reliable and efficient operation of a power system — from a low voltage commercial system serving less than 100kW to a high voltage transmission system delivering hundreds of megawatts — requires a thorough understanding of how the system will perform in both normal operation and during contingencies. The proper and thorough analysis of power systems is required, in both the design and operation stages, in order to maximize safety, reliability, and performance all while minimizing cost.

Because power systems consist of the interconnection of thousands of individual components — transformers, transmission lines, capacitors, voltage regulators, insulators, surge suppressors, switches, and a variety of loads — the analysis of such systems requires an expertise in both the individual components as well as in the complex interaction of these components to form an interconnected system. This requires the proper application of engineering fundamentals developed over a hundred years ago as well as the latest in software tools to quickly and accurately understand complex systems.

ELECT, P.C. has the expertise, experience, and tools to accurately analyze power systems from the design and planning stage to failure analysis, and from the smallest coordination problem to complex transmission loadflow and stability issues, generator interconnection and control, transient disturbances, protective relaying, and more. ELECT, P.C. has developed an expertise and broad experience base in the following areas:

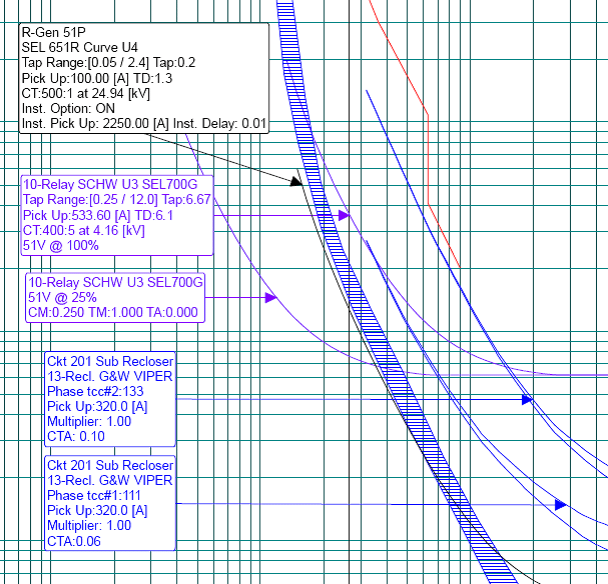

Short Circuit and Protective Coordination

Regardless of the nature of the fault, the reliability and safety of an electrical system requires an understanding of how that system will perform when a short circuit occurs, and a system that is designed and configured to properly respond to the fault. A properly coordinated system will respond to faults by:

- interrupting the fault current to limit equipment damage and minimize hazards to people, and

- minimize the portion of the system that is impacted by the fault.

Utility Distribution Sectionalizing Studies

Consequently, the protection of a utility distribution feeder is more involved than for an industrial feeder as the engineer must not only coordinate overcurrent devices, but also optimize device location and consider several other factors such as reclosing intervals, outage exposure, distributed generation, and utility service philosophies.

ELECT, P.C. has performed numerous utility distribution sectionalizing studies on a wide variety of systems. We have been successful in helping several utilities improve system reliability by implementing improved sectionalizing schemes. ELECT, P.C. has also assisted in sectionalizing studies which incorporate the use of distribution automation, distribution circuit ties with multiple settings groups in microprocessor based controls and fast bus transfer schemes for sensitive large industrial customers.

Load Flow Studies

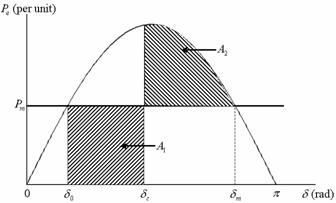

Dynamic Stability

Where multiple generators are applied on a large or isolated system, the response of the system to a fault must be understood so that the overall system returns quickly to a regulated, steady state condition. Dynamic stability analyses allow the modeling of systems in order to predict system performance under various conditions. The results of these analyses can be used to assist to making recommendations for protective relay settings or simply to determine if a design concept is sound. ELECT, P.C. uses commercially available software to perform dynamic stability analyses.

Where multiple generators are applied on a large or isolated system, the response of the system to a fault must be understood so that the overall system returns quickly to a regulated, steady state condition. Dynamic stability analyses allow the modeling of systems in order to predict system performance under various conditions. The results of these analyses can be used to assist to making recommendations for protective relay settings or simply to determine if a design concept is sound. ELECT, P.C. uses commercially available software to perform dynamic stability analyses.

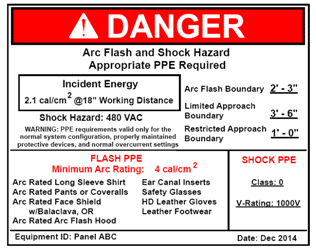

Arc Flash Risk Assessment

Per the National Electrical Code, an arc flash risk assessment is required to be performed for electrical equipment that is likely to require examination, servicing, or maintenance while energized, in order to warn qualified persons of potential electric arc hazards. NFPA 70E requires that such equipment be labeled with specific information relevant to the potential hazard.

The purpose of an arc flash hazard analysis is to determine the incident energy to which a worker might be exposed during an arc flash event, to establish an arc flash boundary, and to determine a worker’s required personal protective equipment (PPE). The PPE is intended to provide a level of protection against arc flash burns, shock hazards, and eye and hearing damage. The use of the required PPE does not necessarily provide protection against all burns, but any burns experienced should be survivable.

ELECT, P.C. also provides personnel training, both awareness training for general employees and qualified worker training for electrical personnel. Arc flash hazard training is a key component of an overall safety program for your employees.

Design Services

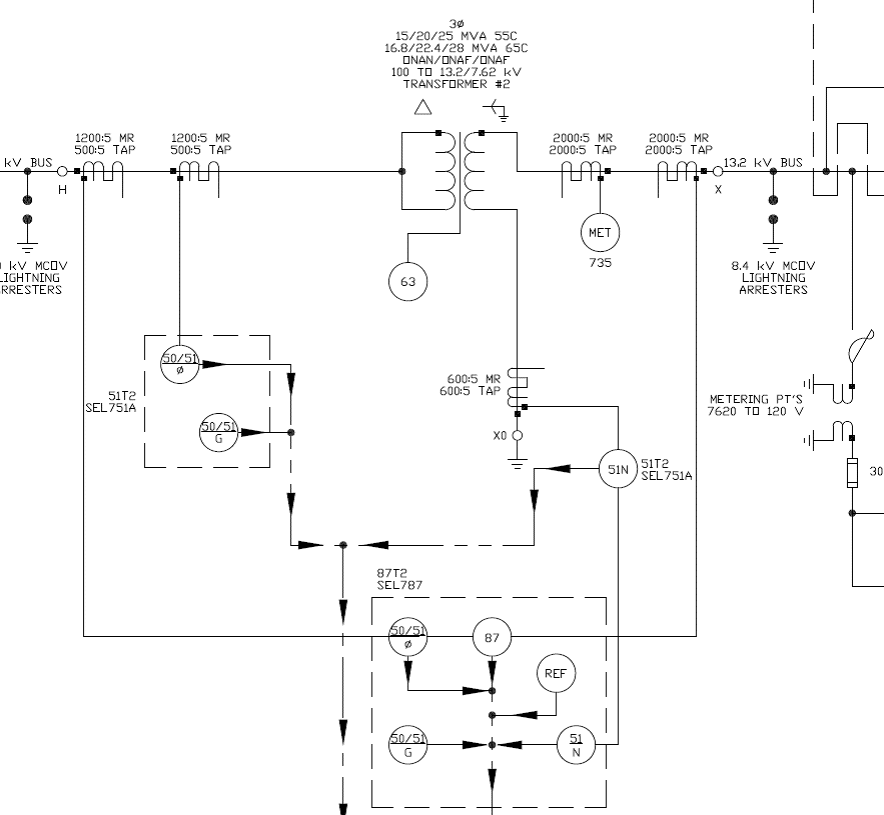

Substation Design

ELECT, P.C. provides complete substation design services, encompassing the entire process from conceptual design to equipment specifications, final BOMs, construction drawings, and commissioning and testing services.

ELECT, P.C. provides complete substation design services, encompassing the entire process from conceptual design to equipment specifications, final BOMs, construction drawings, and commissioning and testing services.

ELECT, P.C. has designed over 50 complete distribution substations, ranging from 15kV, 5MVA to 230x115kV 50MVA.

Protective Relaying Design

ELECT, P.C. has designed protective relaying systems for utility transmission, substations, distribution and generation. We have also designed numerous large scale industrial protective relaying systems. ELECT, P.C. has the expertise to design a protective relaying system that ensures equipment is well protected.

Relay Panel Replacement

ELECT, P.C. can provide a turn-key replacement for outdated systems – we will analyze an existing protective relay system and design a new, completely tested system that provides superior protection, reliability, and functionality using state-of-the art electronic equipment. We can also assist with installation and commissioning of these systems.

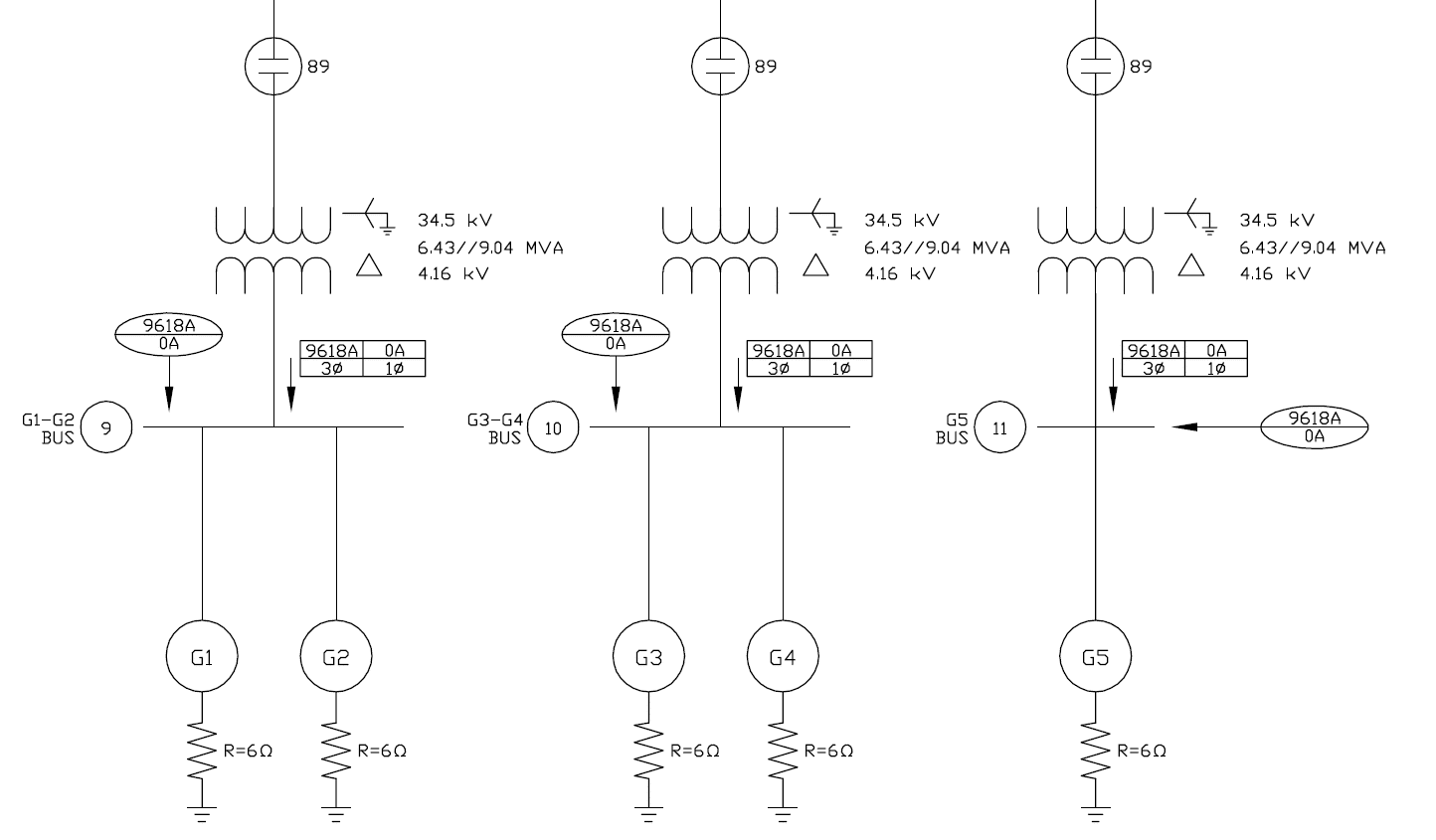

Generator Systems

Generators installed on utility or industrial systems for peak shaving, co-generation, or backup present several engineering, financial, and regulatory challenges. From planning to implementation, these issues must be understood and properly addressed in order for the system to perform as intended.

Generators installed on utility or industrial systems for peak shaving, co-generation, or backup present several engineering, financial, and regulatory challenges. From planning to implementation, these issues must be understood and properly addressed in order for the system to perform as intended.

Generator controls must be properly configured to achieve the desired regulation characteristics, communicate with existing control and protective systems, and properly respond to system load variations.

The protective devices installed as part of a generation package must be properly coordinated with the existing system to adequately protect both the generator and existing distribution equipment, while avoiding problems associated with backfeeding into faults, undesirable system islanding, and negatively impacting existing coordination and control systems.

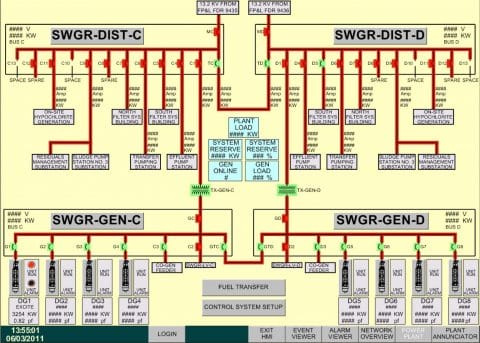

From small, locally operated generators to multi-unit, fully automatic PLC-controlled power plants, ELECT, P.C. can design the generator system to meet your needs.

SCADA, Control, Metering

Remote or off-site control is achieved by integrating the station equipment into the existing SCADA system, providing devices that serve HMI screens via any standard web browser. This allows the owner to monitor and control the system from virtually anywhere.

Using commonly available hardware and software, ELECT, P.C. can provide a SCADA solution for any application. Our knowledge of the industry standard protocols, communications, and custom logic design mean we can integrate into your existing SCADA system or design a new system from the ground up.

Power Quality Investigations

Power quality is, roughly defined, the ability of an electrical system to support loads without the introduction of variations in the source that negatively affect the loads or power system.

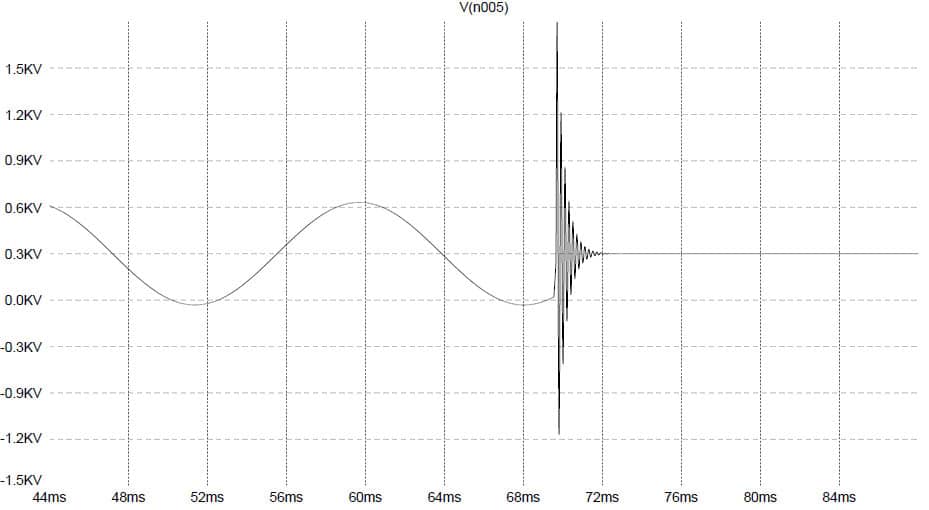

If a system was capable of providing a perfectly regulated, continuous, sinusoidal voltage to an electrical load under all conditions, the power quality of that system might be considered perfect. However, in the real world, this is not the case. Voltages vary over the course of the day. Faults on the system result in momentary deep reductions in voltage. The switching of capacitor banks and some types of faults can result in harmful over-voltages. Poor wiring practices within a facility may compromise the grounding integrity. All of these can result in mis-operation, damage, or nuisance operation of equipment.

The investigation of a power quality problem must go beyond the ability to connect a meter and compile reams of data into a report with little analysis or understanding of the root problem. ELECT, P.C.’s experienced staff will investigate your power quality problem with an understanding of the factors that are and are not relevant, and how changes in the system or remedial equipment will affect the problem. ELECT, P.C.’s diagnostic process will minimizing metering and on-site disruptions, and arrive at a concise recommendation for the most practical and economic solution.

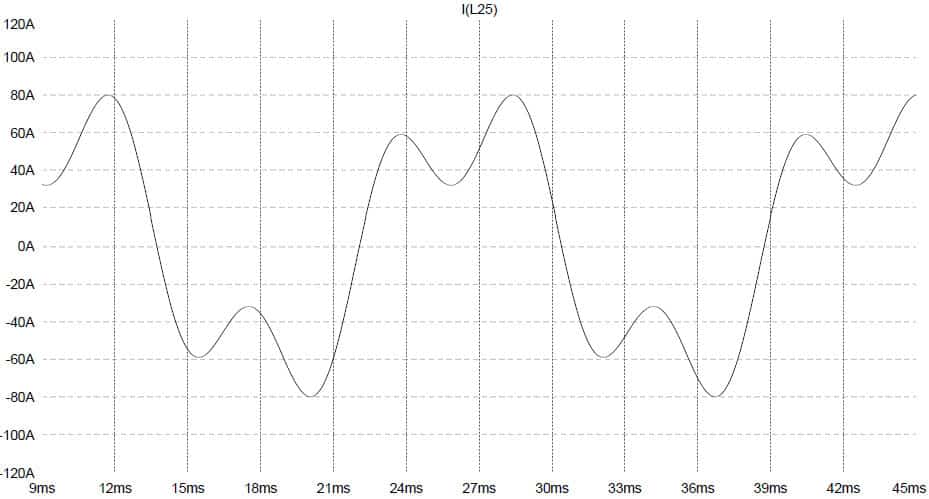

Transient Analysis

However, if a system is not properly protected, protective devices have failed, or transient events are not severe enough to be clamped, a well-designed system can still experience problems. Because transients are often unpredictable, the metering and diagnosis of the exact problem is often very difficult.

ELECT, P.C. can identify and measure power system transients and model these using software, if necessary, in order to diagnose or solve transient-related power systems problems.

Harmonic Analysis Studies

Motor Starting Studies